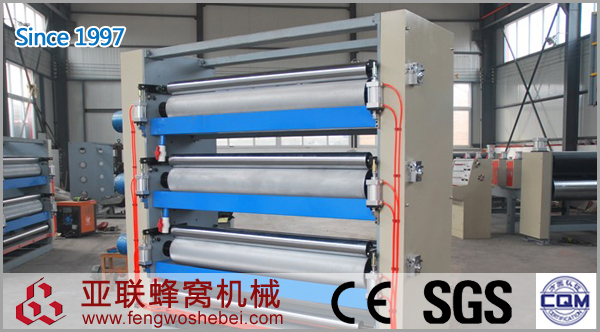

Multi-layer coating machine |

Gluing machine function and characteristics The glue applicator is used to apply the glue evenly on each layer of base paper. Different coating methods can be selected according to different paper types, and the amount of glue applied is about 15-30g/m2. Each set of glue-coating mechanism is independent variable frequency drive, and it can be started synchronously with the production line, and the glue speed can be synchronized with the production line.The rubberized part of the cardboard production line is an important part of the production line. Its main purpose is to guide the paper and the base paper onto the rubberized shaft through the paper guide shaft, and the pressure shaft is guided through the cylinder to make it evenly glued. . Main technical indicators and parameters: 1. Cardboard width: 1600mm 2. Maximum speed: 80m/min 3. Economic speed: 20~60 m/min The main features of the structure: The whole machine runs smoothly and the noise is small. The paper guide shaft is chrome-plated after finishing grinding. This is not only beautiful and beautiful, but also important to ensure high precision and wear resistance. It does not rust during work. After the rubber shaft is pressed, the hard chrome is hardened. It makes it wear-resistant and does not rust. The rubberized shaft is an acid-resistant rubber shaft, which is processed by precision. Adjustment mechanism: The glue is injected into the glue through the glue pump, glued through the mesh shaft, and then the gap of the rubber shaft is adjusted to match the mesh shaft by adjusting the hand wheel. The pressure of the anastomosis is adjusted by the amount of glue, and the solenoid valve is passed. The switch is controlled so that the upper pressure shaft is pressed against the rubber shaft, and finally the glued base paper is introduced into the compaction portion. |