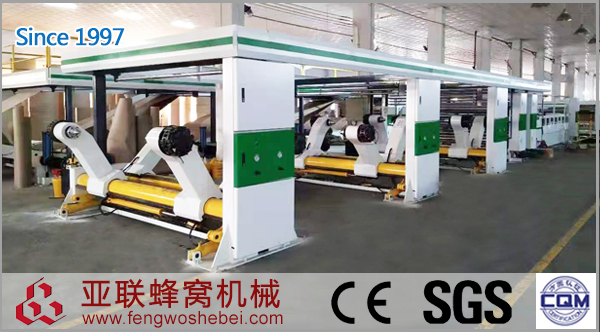

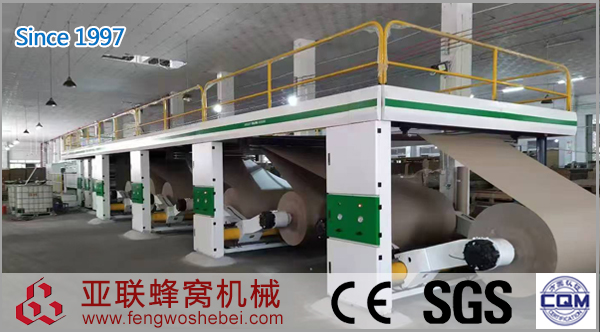

ZDFX-1600 honeycomb paper core production line |

A performance feature (1) The production line is capable of fully automatic production of honeycomb paper cores in one stop. The production process starts from high-strength corrugated paper to directly out the cut honeycomb paper core, and introduces foreign advanced technology to eliminate the paper cutter and docking machine required for traditional production of honeycomb paperboard. The biggest advantage of this line is high automation and low labor costs.(2) Horizontal cutting, advanced structure and fast cutting speed. (3) Applying rubber with a toothed roller, the honeycomb aperture is evenly ruled (has applied for national invention patent) (4) The production line has high degree of automation, advanced technology, low loss, and the yield of honeycomb paperboard reaches 98%. (5) Full computer PC control, using advanced electrical design, collecting machine, electricity, gas, light, liquid in one, the calculator can touch screen operation. The workers are simple and convenient to operate, stable and reliable in performance, and are at the leading level in the domestic counterparts. (6) From the raw paper into the cardboard, it is completed once on the fully automatic production line. The operator only needs 2 to 3 people, and the raw paper has high utilization rate and advanced technology.  The process flow is as follows: Multi-roll paper at the same time on paper → glue line → composite drying forming → cross cutting → automatic collection and dockingThree main technical parameters: Model: ZDFX-1600 Base paper maximum width: 1600mm Maximum width of core material: 1600mm Core width (after stretching) 1300mm Core paper cross cutting speed: 550 times / minute Gluing method: gear transfer coating / glue spraying system Number of paper rolls: 6 rolls Honeycomb core thickness: 6-100mm Honeycomb side length: 4-40mm (customers choose two or four) Power: 50KW

Production line size: 24000*3600*2500mm Applicable paper: high strength corrugated paper (100-180g/m2) Adhesive: white latex, starch glue, etc. Total weight of equipment: 30T |