Door industry, furniture automatic honeycomb paper core production line | ||||||||||||||||||||||||||||||||||||||||||||||||

First, automatic honeycomb door industry paper core equipment background There are generally four ways to produce paper cores in the domestic cellular door industry. (1) Manual type: There is a simple glue applicator and two platforms, one side feeds the paper and the other side picks up the paper stack. This backward production method can not meet the requirements of manufacturing honeycomb core. (2) Eight ways: The equipment is mature, the structure is stable and reliable, the operation is simple, and the paper core is regulated. The utilization rate of raw materials is around 90%, and the investment is less effective. Good quality and low price. (3) Cascading type: The two-paper or four-paper stacked honeycomb mechanical equipment is slightly higher in automation, the workshop environment is good, and there is no dust, but the core making speed is slower than the eight-way method. Raw material utilization rate is around 92% Remarks: (The above three production methods need to be equipped with a paper cutter) (4) Automatic honeycomb door industry paper core equipment is a new generation of paper core production line developed by the factory to absorb the characteristics of foreign equipment combined with China's actual situation. The technology is advanced, the production speed is fast and the labor cost is greatly saved. The base paper utilization rate is 98% from the base paper. Once the finished product is molded, the offline can be packaged and shipped. This equipment does not require a paper cutter, and the investment cost will not be much higher than the production methods of the first three.

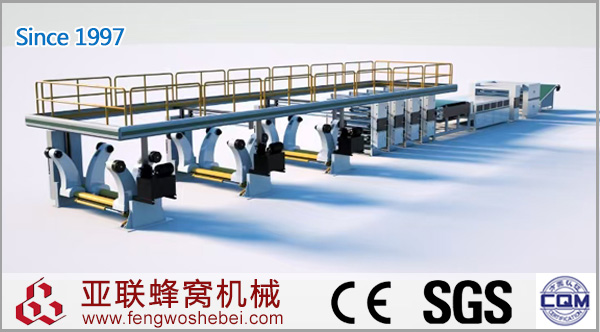

Multi-roll paper at the same time on paper вЖТ glue line вЖТ composite drying form вЖТ cross cut вЖТ automatic collection and connection вЖТ package delivery Third, the full line technical parameters

|