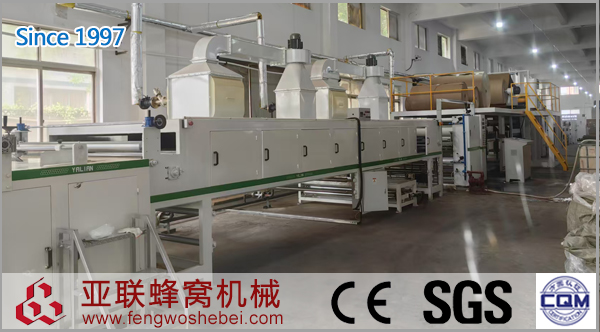

ZDFB1600 honeycomb paperboard production line |

First, equipment characteristics 1. The production line adopts multi-stage interval ovens, which are repeatedly heated and cooled to achieve the effect of quickly drying honeycomb paperboard. This ensures that the machine can run at high speed. The bonding fastness and flatness of the honeycomb paperboard are very good.2. The production line adopts PLC control and touch screen operation. The machine has a production record function, timely real-time paperboard output, user-friendly statistics 3. The glue coating mechanism can realize the surface paper coating or the core paper coating glue, and the machine can be used for both. The rubber amount is controlled by rubber roller, the glue amount is uniform and the precision is high, which can reduce the cost of glue. 4. This machine adopts servo motor drive and ball screw transmission for synchronous tracking and servo cutting to ensure the accuracy of cardboard cutting. 5. There are major technological breakthroughs in design, more reasonable, high yield, and a significant cost reduction. 4-5 people in a single class can produce more than 10,000 m2.  Second, the honeycomb paperboard production process is as follows: Multi-roll paper at the same time on paper → glue line → composite drying forming → cross cutting → automatic collection and butt → paper core stretching and drying → paper core coating or paper coating → face paper → paper composite → pressure Drying (electric heating or steam) → fan cooling → fixed length cutting → automatic collection of stacking codeThird, the specification parameters: Machine model: ZDFB-1600 The maximum width of the paper core: 2000mm Maximum width of facial tissue: 1600mm Maximum width of cardboard: 1600mm Cardboard thickness: 6-90mm Production speed: 0-30m/min Cardboard cutting accuracy: 1000±1.5mm Heating method (optional): electric heating, steam heat, oil heating Total power: 180 -200KW Dimensions: 73000x4500x3500mm Equipment weight: 60000KG |